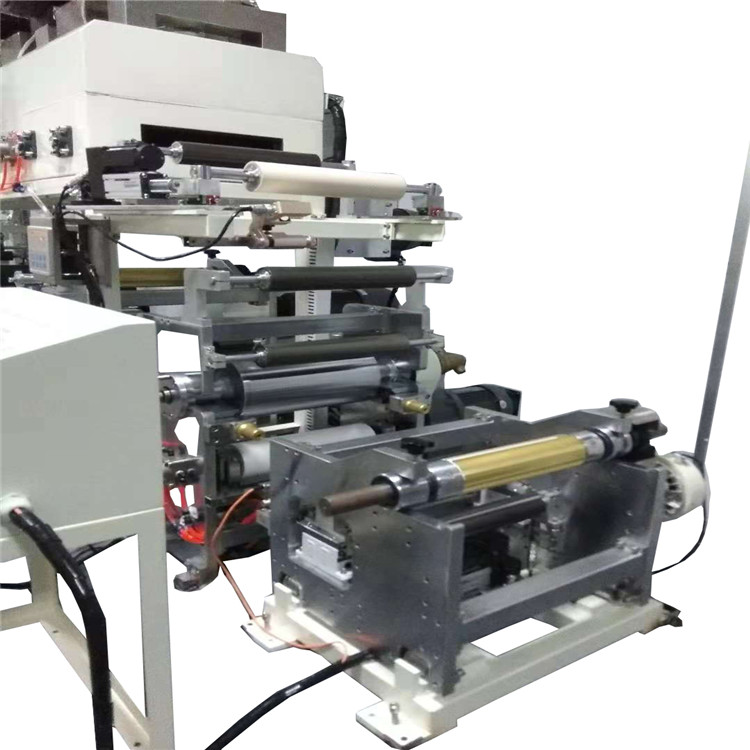

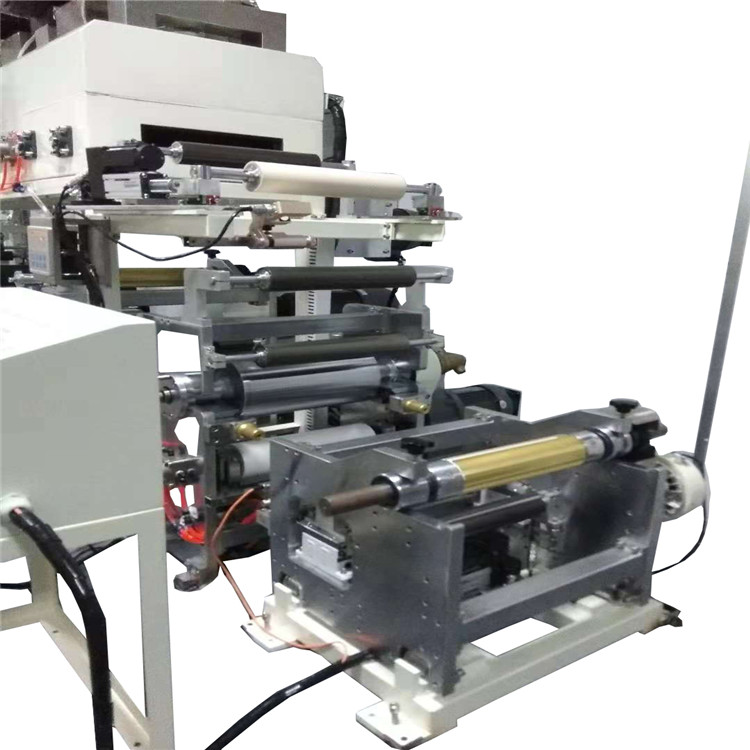

Water-based Glue Samples Printing Coating Machine Price

1.Product Description

1.1 This production line is suitable for producing coating of PET,

BOPP, PP, paper, etc. (suitable for scraping, etc.)

1.2 Mainly use raw materials

1.2.1 Substrate: PET, BOPP, PP, paper, etc

1.2.2 Glue: oily and water-based glue, etc

2. Coating machine production line performance and technical parameters

2.1 Coating machine substrate width 250mm

2.2 Maximum external diameter of winding 200mm

2.3 Maximum external diameter of winding 200mm

2.4 Diameter of unwinding mandrel, 3"

2.5 Coil mandrel size 3"

2.6 Coating uniformity dry adhesive ≤ 0.0025mm

2.7 Coiling edge uniformity end face alignment error ≤3mm

2.8 Production speed 0.5-10m/min

2.9 Machine speed 10m/min

2.10 Heating and drying mode electric heating (tunnel type hot air

drying) ladder heating mode (low-high-low distribution)

Maximum adjustment temperature: 180℃

Power 3 2.11, 380 v, 50 hz

2.12 Compressed air source 6-8kg/cm2

2.13 Three-phase alternating current of heat source

2.14 Flat and straight layout of oven

3. Details of main equipment

3.1 The production line supports the body and accessories type 1

3.2 Single working position feeding machine 1

3.3 One straight scraping coating head

3.4 Oven (0.7m/section) 3 sections

3.5 Compound mechanism 1

3.6 One laminating feeding machine

3.7 One single shaft winding machine

3.8 Electronic control system type 1

3.9 Piping project type 1

3.10 Wiring engineering type 1

3.11 Piping engineering type 1

3.12 Transmission system type 1

Main specification:

| Oven size: | 2.1Meter, 3 part, every part 0.7 meter in length. |

| Machine size: | 3.3M*1.35M*2.5M(L*W*H) |

| Heating 3separated part electric heating up | 0~200℃ adjustable |

| Temperature misreading | ±3℃ |

| Max. diameter of roller release and collect: | 250mm |

| Max. coating width | 300mm |

| Coating speed: | 0.5-10mm/min |

| Max. coating thickness (materials with glue) | 1000 micron |

| Min. coating thickness (only glue) | 10 micron |

| Coating gap(can be customize) | 0-0.5mm |

| Coating accuracy | 0.001mm 0.002-0.003mm |

| Minimum glue (adding way) | About 200g (Manually) |

| Power | 380v/50hz, about 10kw (electric heating power about 5kw) |

2.Product Design Standard

ASTM D903, GB/T2790/2791/2792, CNS11888, JIS K6854, PSTC7, GB/T

453, ASTM E4, ASTM D1876, ASTM F2256, EN1719, EN 1939, ISO 11339,

ISO 36, EN 1465, ISO 13007, ISO 4587, ASTM C663, ASTM D1335, ASTM

D5733, ASTM D2261, ASTM F2458, EN 1465, ISO 2411, ISO 4587, ISO/TS

11405, ASTM D5034, ASTM D4632.

Onsite Service:

1.Device installation 2.Equipment Operation Test Technology

training 3. Equipment Calibration 4.Daily maintenance and

maintenance of equipment

Free technical training for visiting factories 24-hour Online

contact

Free software upgrades

Free information:

1.Product Instruction;2.Product operation

instruction/video;3.Experiment Test (test application, test report)

Device Problem Handling:

1. Social media 24 hours online communication;2. Mail Seamless

Docking;3. Video Conferencing;4. Artificial free door-to-door

service